previous page: Pump Circuit

CHOKE CIRCUIT

The choke system is incorporated in the carburetor, for the purpose of richening the mixture ratio for cold and semi-warm engine starting and operation. The choke is built into the carburetor air horn and consists of a round flat valve that has almost the same circumference as the inside of the air horn. It is mounted on a shaft that reaches from side to side in the air horn.

One end of the shaft extends out of the air horn and has a linkage attached to it for either manual or automatic operation.

By closing the choke valve and restricting the flow of air to the minimum in the air horn, the mixture is richened for cold engine starting. As the engine gradually becomes warm the choke valve is gradually opened.

After the engine reaches operating temperature the function of the choke circuit ceases. On a carburetor having a hand or manually operated choke system, this action is controlled by the operator of the vehicle.

With the automatic choke, it is just what the name implies, completely automatic. Of course, the automatic choke can only operate properly when it is clean and calibrated to specifications.

There are two general types of automatic chokes:

1. Manifold type-mounted on engine manifold and connected by linkage to carburetor choke valve. 2. The type built integral with the carburetor.

The manifold type most commonly used is the "Sisson Choke." There is only one adjustment the mechanic can make on this unit without the factory recommended equipment. That is the "full" choked setting. This can be done as follows: The choke linkage operating shaft has a hole drilled through it. The base of the choke housing has a recess cut in it. Using a cotter pin or drift pin, insert whichever one used in the shaft hole and drop it through so it will fit into the recess in the housing hole.

The choke is now set for full choking action. Loosen the nut of the arm on the choke shaft with the link rod connected. Close choke valve in carburetor. Holding the choke valve closed, tighten arm nut. Remove cotter or drift pin from shaft hole. The choke is now ready for operation.

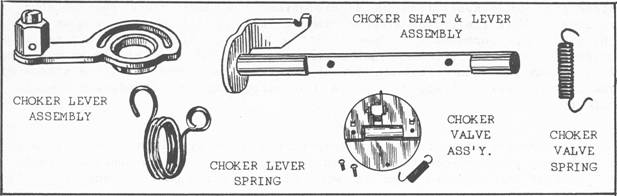

The automatic choke built as part of the carburetor is a simple, ingenious device and is practically fool proof. Its greatest enemies are dirt, carbon and improper adjustment. The parts of the automatic choke are as follows: choke housing and air horn assembly which has the hot air inlet and vacuum piston cylinder and vacuum inlet port cast in it, off set choke valve, fast idle linkage, hot air passage screen, choke valve shaft, screws and vacuum piston and link. It also includes thermostatic coil spring housing and mounting screws and retainers. The last two parts of the automatic choke circuit are the hot air passage and the vacuum passage.

The automatic choke principle is very simple. When the engine is cold, the thermostatic coil spring contracts or coils up. The spring has a bend in the end which fits over a projection on the choke valve shaft. This causes the spring to wind up and the choke valve closes. When the engine is started, vacuum is applied to the vacuum piston which is also connected by a link to the choke shaft. This piston tries to pull the choke valve open, but due to the tension of the thermostatic spring, the choke valve is held in just the correct position, for proper starting mixture in accordance with weather or engine temperature. As the engine warms up, heat from the exhaust manifold is piped into the choke operating housing, and as the thermostatic spring grows warm it uncoils. The vacuum piston pulls on the choke shaft and finally opens the choke all the way.

Some complaints are flooding or loading. This is caused by over choking.

Assuming that the thermostatic spring has not been damaged or changed, some of the causes of over choking are:

1. Hot air passage or screen blocked solid with dirt or carbon. This will restrict or stop the flow of hot air into the coil spring housing. 2. Spring set too tight. This will delay the choke opening until long after the engine has reached operating temperature. 3. Choke valve or shaft binding in air horn. 4. Loose thermostatic spring cover allowing air to enter housing, preventing the spring from reaching the proper temperature.

On the other hand, another complaint is leanness or hard cold starting. 1. Vacuum piston relief ports stopped or restricted with carbon. This will cause a vacuum pull so strong on piston, it will open the choke valve too wide. 2. Loose housing cover. This will bleed air into the intake manifold leaning out the mixture.

In resetting or adjusting any automatic choke, consult the specification of the unit being repaired.

The foregoing text covers the Principles of Carburetion, also the construction of the circuits, their functioning and causes of improper operation of these circuits. Because all downdraft carburetors operate on the same basic fundamentals, this text can be applied to any downdraft carburetor the serviceman may encounter. However, the story applies mostly to the "Single Barrel" type downdraft carburetor. Since there are some structural differences in the "Double Barrel" or "Dual" type carburetors they will be discussed in the pages that follow.

next: Anti-Percolation

Table of Contents

The Carburetor and Its Purpose

- Carburetor Construction and Circuits

- Float Circuit

- Low Speed Circuit

- High Speed and Power System

- Pump Circuit

- Choke Circuit

- Anti-Percolation

- Dual Carburetors

- Low Speed Circuit

- High Speed Circuits

- Pump Circuit

- Choke Circuit

- Compound Carburetion

Tune-Up of the Gasoline Engine

- Compression

- Ignition

- Carburetion

- Short Cuts in Trouble Shooting

- Vacuum Gauge Tests While Engine Is Running

- Correct Setting of Ignition Timing With Vacuum Gauge

- Instructions for Use and Purpose Of Compression Gauge

- Testing the Ignition Circuit

- How to Make Test With Analyzer

- Procedure of Test

- Road Testing