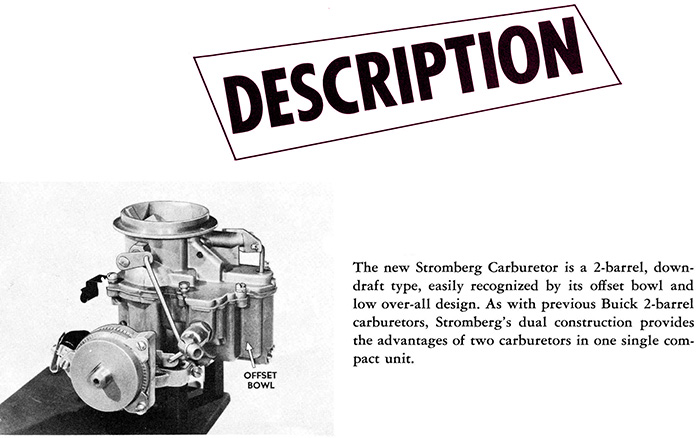

The Stromberg WW is a two barrel downdraft carburetor first introduced in 1953 and used on various US car and truck models until 1974 and in Australia on Holden vehicles until 1980. Buicks started using these in 1955.

Usage by Make

- Buick 1955-1961

- Chevrolet 1955-58

- Chrysler 1955-57

- Dodge 1953-70

- Desoto 1955-57

- GMC 1960-74

- Holden 1958 -1980

- Oldsmobile 1954-55

- Plymouth 1955-67

- Pontiac 1955-56

- Studebaker 1953-64

Versions - WW and WWC

There were main two versions, the smaller WW which fit a standard SAE 1 1/4” flange and the larger WWC which mounted on the larger 1 1/2” flange. WWC carburetors were used on larger Mopar V8s and on some GMC engines. The two can be distinguished by the location of the accelerator pump acutator. On the smaller units, the pump protrudes through the top of the airhorn and is moved by a lever (Stromberg WW). On the larger version, the pump is internal and is actuated on the side by the pump rod (Stromberg WWC).

Comparison of Stromberg WW and Carter BBD

Stromberg WW and WWC carburetors were used on 50s and 60s Mopar applications along with Carter BBD carburetors, with which they are often confused. They can be distinguished by the location of the fuel inlet fitting: Carter BBDs have the fuel inlet coming out the front, whereas Stromberg WW and WWC carbs have the fuel inlet coming out the side.

Restoration Notes

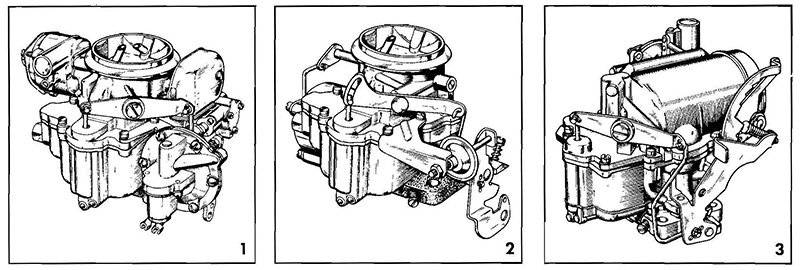

Figures 1 and 2 show typical WW carburetors with a vertical air intake. Figure 3 shows a typical WW carburetor with a horizontal air intake.

The carburetors came in both automatic and manual choke versions. The auto choke types used an integral choke where the choke housing is mounted on the throttle body primarily on Buicks and a few other models. Later Mopar versions used a manifold-mounted crossover choke. Carburetors with integral chokes used a choke piston as a vacuum break to open the choke on starting; remote choke carbs used a diaphragm type choke pull off.

In the types shown in Figures 1 and 3 the automatic choke control and fast idle cam mechanism are attached directly to the choke shaft . In the type shown in Figure 2, the automatic choke control and fast idle mechanism are part of the throttle body and are connected to the choke shaft through a rod and lever.

Some models incorporate accessory equipment, such as: overdrive kickdown switch, magnetic dashpot control, and kickdown limit switch. Figure 1 shows model with kickdown limit switch and magnetic dashpot control. Some Buick carburetors used a starter switch, similar in construction to other Buick carbs.

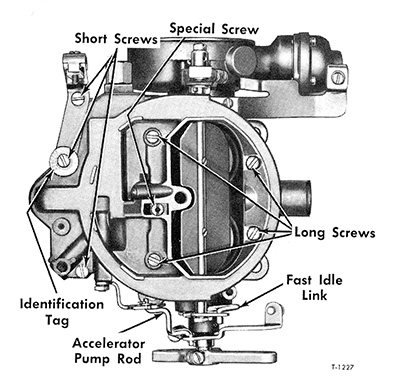

All Stromberg WW carburetors have the identification code number stamped on the air horn cover, adjacent to the fuel inlet. Before attempting to repair or overhaul a carburetor, refer to the identification code number and secure the correct repair kit for the carburetor that is to be repaired.

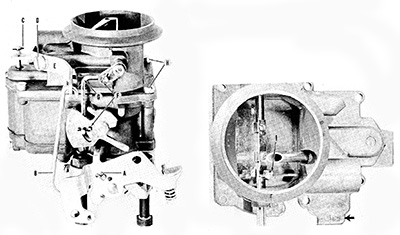

The Stromberg WW consists of three main castings. The throttle body is aluminum and the float bowl and airhorn (float bowl cover) are zinc, finished in a gold-green chromate conversion coating. The castings are lightweight and are prone to warping. The throttle bodies often have play around the throttle shafts. This is due to both wear in the throttle body itself and wear on the shaft. This can be repaired by installing bronze bushings in the throttle body to take up the slack. The throttle bodies often need to be planed flat in order to eliminate air leaks around the base gasket. The float bowls on the larger WWC carburetors are often badly distorted because of strain from the air cleaner mounting stud pulling up on the casting. These can often be trued by heating in an oven or with a propane torch and pressing flat in a jig. Zinc melts in the hot part of a propane flame, so caution must be used to avoid destroying the casting.

Some large WWC carburetors used on GMC Truck applications use a special flange where the front and back mounting bolts are a different width apart. These are unique and there is no other carb that will fit these manifolds directly.

Heavy duty truck versions often used an integral governor in the throttle body. A few Taxis were also equipped with governed carburetors.

Further Information

stromberg ww carburetor kits

- CK17

WW for Dodge, GMC, Plymouth, Pontiac

- CK41

WWC for Chrysler, DeSoto, Dodge, Plymouth

- CK49

WW for 1962-64 GMC V6, V12

- CK50

WW for 1965-68 GMC Truck V6 305" C, E

- CK4491

WW for 1955-61 GMC

- CK4492

WW for 1955-64 Studebaker

- CK501

WW for 1955-56 Dodge, Dodge Truck

- CK5011

WW for 1953-55 Dodge V8

- CK5012

WW for 1955 Dodge V8

- CK5013

WW for 1955-56 Dodge, Dodge Truck

- CK525

WW for Chrysler, DeSoto, Dodge, Dodge, Truck, Plymouth

- CK5251

WW for 1956-59 Mopar

- CK5252

WW for 1957-58 Dodge

- CK5253

WW for 1965-68 GMC

- CK526

WW for Chevrolet, Chrysler, DeSoto, New Idea Farm Equipment, Studebaker

- CK5261

WW for 1957-58 Studebaker Supercharged

- CK5281

WW

- CK529

WW for Buick, Dodge, Truck, GMC, Gray Marine

- CK5431

WW for 1958-60 Buick

- CK5432

WW for 1957 Buick

- CK573

WWZ for Allis Chalmers, Chrysler Industrial, Ford Tractor

- CK744

WWC