previous page: Compression, Ignition and Carburetion

SHORTCUTS IN TROUBLESHOOTING

Although a Vacuum Gauge doesn't speak, it does the next thing to it. It's the one instrument of vital necessity in diagnosing troubles in late model high- compression engines. But the mechanic must first understand the fundamental basic principles of a gasoline engine; after that, the various readings on the Vacuum Gauge dial each have a definite meaning.

The compression factor of an engine can be checked with a Vacuum Gauge by making a VACUUM LIFT TEST. This test can be made in a few minutes. It should be remembered, however, that the vacuum lift test should be made only to determine whether the compression is normal. If the lift test is poor, an individual cylinder compression test should be made with a conventional compression gauge, and this will isolate the faulty conditions as they may exist in the individual cylinders.

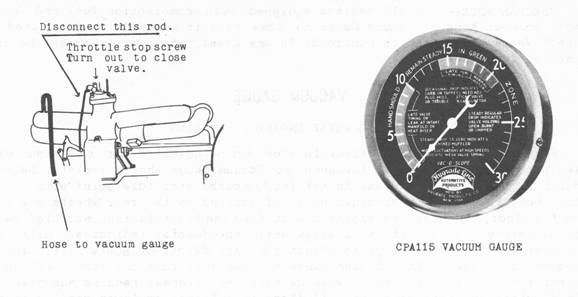

The vacuum lift testis made by connecting the gauge directly to the intake manifold with the rubber hose and adapter furnished for that purpose. Disconnect throttle arm connector link and turn throttle arm stop screw out far enough to completely close the throttle valve in carburetor body. Then, with the ignition switch in the "off" position, turn the engine over with starter. (If the starter switch must be turned on for starter motor current, disconnect distributor cap. This will prevent the engine from starting. Pulling out the high tension wire of the coil will produce the same result.)

Now watch the hand on gauge. As the starter turns over the engine, the vacuum gauge hand will rise on the dial to a point where it stands when engine is idling under its own power. If everything is perfectly normal, the hand will lift to 17" or more of vacuum, with a very slight vibration which is caused by engine valve overlap because of the low R.P.M.'s the engine is turning over. If a normal reading of 17" or more is obtained, the engine compression is normal.

If the hand doesn't lift higher than 5", the intake manifold, the manifold gaskets, or the heat riser sleeve is faulty or leaking, and should be removed and checked.

If the hand rises to a point between 10" and 15" and vibrates back and forth badly, it indicates a blown cylinder head gasket or a bad valve condition. In either case, by making an individual cylinder compression test, you can isolate the condition before removing the cylinder head for the necessary repairs.

SPECIAL NOTE:- On all engines equipped with combination Fuel and Vacuum pumps, connect hose of Vacuum Gauge to same hole in manifold that is used to connect Vacuum Pump Line to manifold. In any event, the pump line must be disconnected from manifold.

Table of Contents

The Carburetor and Its Purpose

- Carburetor Construction and Circuits

- Float Circuit

- Low Speed Circuit

- High Speed and Power System

- Pump Circuit

- Choke Circuit

- Anti-Percolation

- Dual Carburetors

- Low Speed Circuit

- High Speed Circuits

- Pump Circuit

- Choke Circuit

- Compound Carburetion

Tune-Up of the Gasoline Engine

- Compression

- Ignition

- Carburetion

- Short Cuts in Trouble Shooting

- Vacuum Gauge Tests While Engine Is Running

- Correct Setting of Ignition Timing With Vacuum Gauge

- Instructions for Use and Purpose Of Compression Gauge

- Testing the Ignition Circuit

- How to Make Test With Analyzer

- Procedure of Test

- Road Testing